Our E-beam and X-ray irradiation systems provide a safer, cost-effective and flexible way to sterilize medical products and food

STERILIZATION

A NEW LEVEL OF SAFETY AND PROCESSING EFFICIENCY

Linac-based electron beam sterilization solves the growing health concerns around use of Ethylene Oxide (EO) and rising costs and limited supply of Co-60 gamma irradiation. Unlike EO, products can be released immediately and without the decreasing capacity issues of gamma irradiation. The food processing industry faces similar issues. RadiaBeam provides safe, high-performance solutions with the flexibility to offer components or complete irradiator systems for medical device sterilization or food processing.

MEDICAL DEVICE STERILIZATION: REPLACE HIGH-RISK EO WITH HIGH-ENERGY ELECTRONS

Replacement of Ethelyne Oxide (EO) has become a priority for medical device sterilization facilities where unsafe levels of EO released into the environment can impact worker and public safety. EO “offgassing” from “hot pallets” post-aeration can continue at every point in the supply chain: transportation, distribution centers, and destination warehouses. Lawsuits are on the rise. RadiaBeam’s linac-based alternative is a clean and safe irradiation solution.

SINGLE COMPONENTS OR COMPLETE STERILIZATION SYSTEMS, ALL MADE IN THE USA

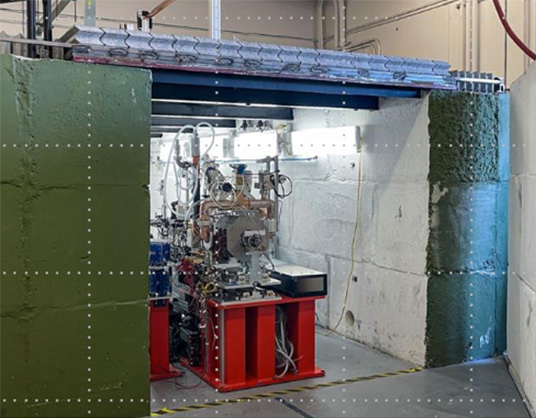

Whether you are looking for a drop-in-ready component on an OEM basis, or a turnkey system for your new sterilization facility, RadiaBeam is your go-to resource. We design, manufacture, and test all our products at our USA facility which includes four radiation-shielded test-cells (see photo). Our turnaround time is faster and our expert team will consult with you at every phase to be sure you get the exact power and throughput that you need. Plus, you avoid supply shortfalls due to foreign wars, not to mention conflicts of interest due to mergers.

WHAT’S YOUR DOSE TARGET? MAXIMIZE THROUGHPUT, PENETRATION, AND EFFICIENCY

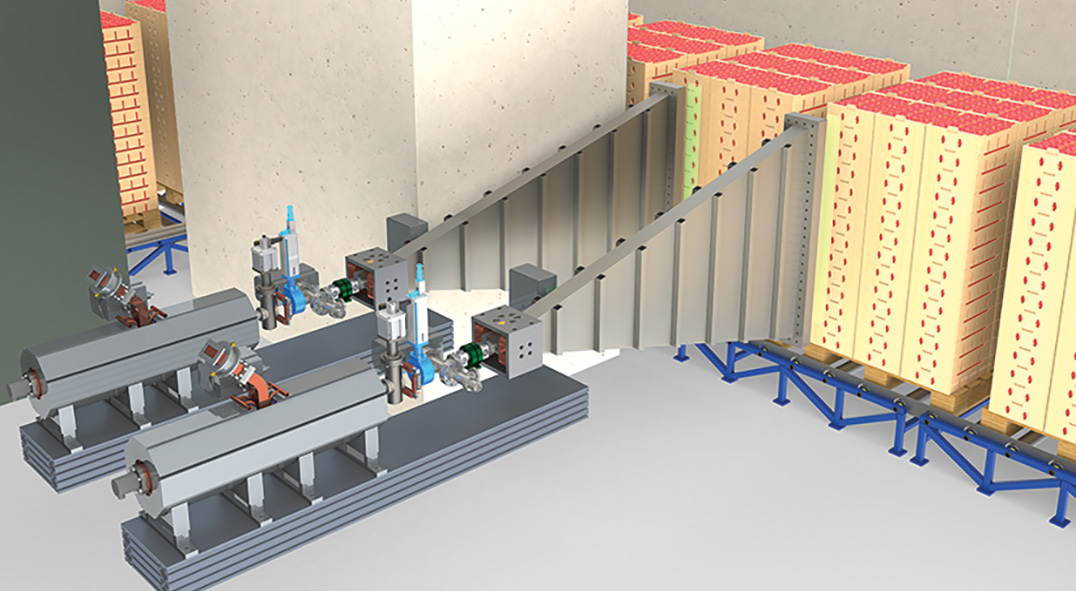

Name your dose target in KiloGrays (kGy) and throughput in kg/hour and we will recommend a solution to meet your goal, whether lower power for food, or high power for economical and efficient medical device sterilization. Integrate RadiaBeam irradiators into your production line, to deliver electron beams or X-rays that achieve optimum penetration at speed, as cartons with medical disposables or food move along the conveyor. The electrons generated can be used directly for highest throughput, or can be converted to X-rays for greater penetration through larger packages or entire pallets.

RADIABEAM INNOVATION: A MODULAR LINAC FOR PARALLEL IRRADIATION

RadiaBeam continues to lead the industry with continuous innovation. With the goal of reducing the cost of high-power linacs, we have developed modular 3 – 5 MeV linacs with variable energy, an adjustable scanning system, and competitive cost. Multiple modular linacs can replace a single larger linac, allowing flexibility and scalability while improving redundancy and economics.

Read more about RadiaBeam irradiators