A UNIQUE SYNERGY

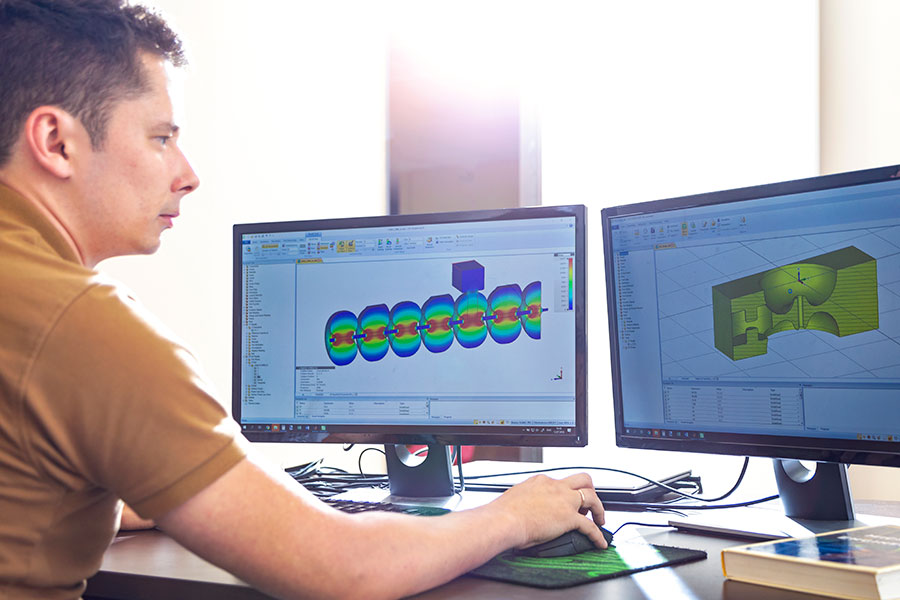

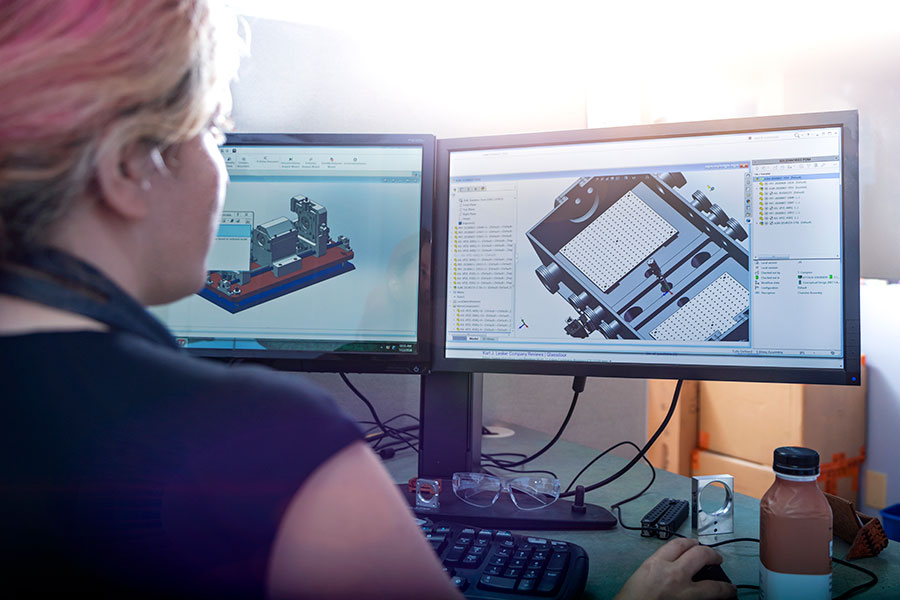

RadiaBeam is unique in the particle accelerator field due to the synergy between the research and commercial sides of our business. Each enhances the other. We apply multi-disciplinary expertise at the frontiers of science to produce solutions that work. We transform ideas into physical reality.

Research

Solutions to advanced problems in beam physics, security, medical applications of radiation, and microwave technologies.

Commercial products

Custom particle accelerator components, Linacs and complete systems for any E-beam or X-ray application.

A CULTURE OF COLLABORATION

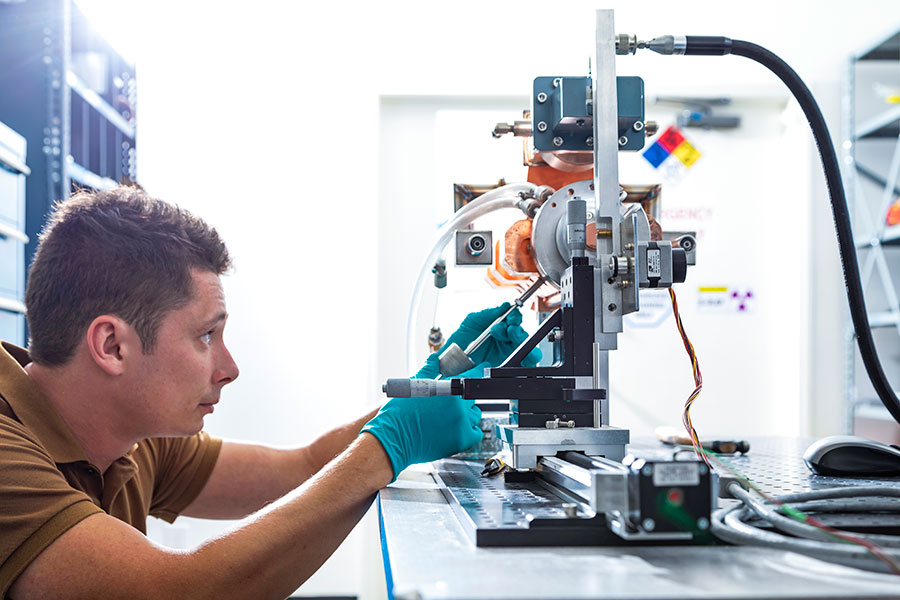

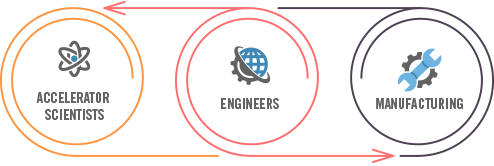

With RadiaBeam, you get more than just a product or R&D project. You get an experienced and established team of multi-disciplinary accelerator scientists, engineers, technicians and manufacturers who are passionate about adding value at every step. We will discover ways to improve a component or system beyond your specifications. We custom design and manufacture products and solutions that will take your application to the next level. You will find us a pleasure to work with!

Our engineers work with you, our scientists, and the manufacturing staff in our facility to transform ideas into physical reality. A true collaborative process.

TOUR RADIABEAM

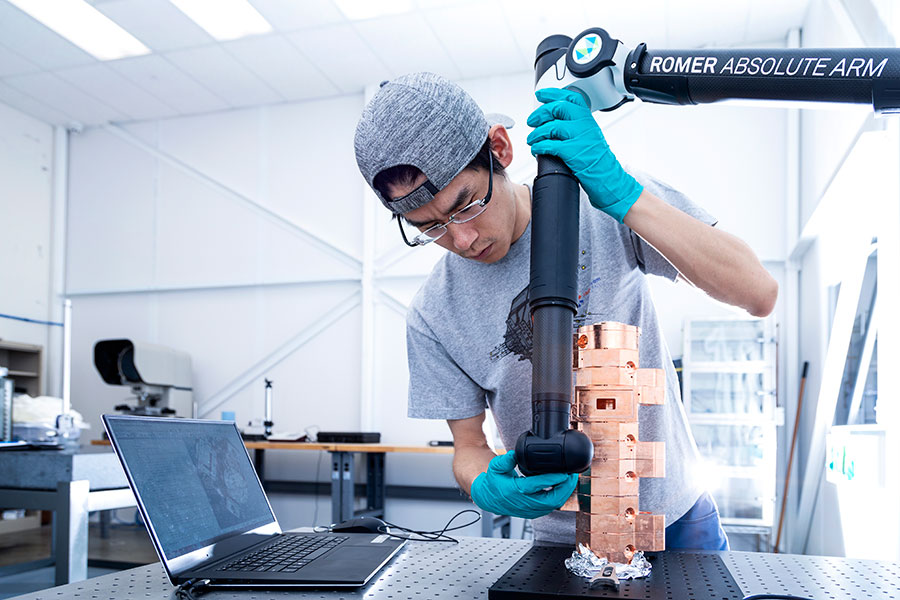

From initial design to testing to final manufacturing, our 30,000 sqft (2800 sqm) facility is fully equipped and staffed. We’re your one-stop shop for accelerator technology.

An E-beam source that takes your products further

When you need an E-beam or X-ray source for an innovative next-generation product or system, come to us. We will fine tune the design, then manufacture and validate the device so it’s drop-in-ready. Our linac systems and components are integrated into radiation therapy, cargo inspection, food sterilization and other commercial systems that are revolutionizing their industries.

Looking for higher beam quality, better throughput, smaller footprint, or lower manufactured cost? RadiaBeam is your source. Learn more

An E-beam source that takes your products further

When you need an E-beam or X-ray source for an innovative next-generation product or system, come to us. We will fine tune the design, then manufacture and validate the device so it’s drop-in-ready. Our Linac systems and components are integrated into radiation therapy, cargo inspection, food sterilization and other commercial systems that are revolutionizing their industries.

Looking for higher beam quality, better throughput, smaller footprint, or lower manufactured cost? RadiaBeam is your source. Learn more

We accelerate completion of greenfield facilities from the ground up

If you’re building an entire “greenfield” facility, whether it be a sterilization facility or a turnkey beamline, let us support your buildout in any capacity. Outsource all or any part of the project to us: design, commissioning, manufacturing, components, integration, installation, testing and full qualification. Use our resources and expertise to supplement your team, reduce cost, and stay on schedule. More than just components, you have access to RadiaBeam’s 20+ years’ history in system design, fabrication, integration, and testing.

We accelerate completion of greenfield facilities from the ground up

If you’re building an entire “greenfield” facility, whether it be a sterilization facility or a turnkey beamline, let us support your buildout in any capacity. Outsource all or any part of the project to us: design, commissioning, manufacturing, components, integration, installation, testing and full qualification. Use our resources and expertise to supplement your team, reduce cost, and stay on schedule. More than just components, you have access to RadiaBeam’s 20+ years’ history in system design, fabrication, integration, and testing.

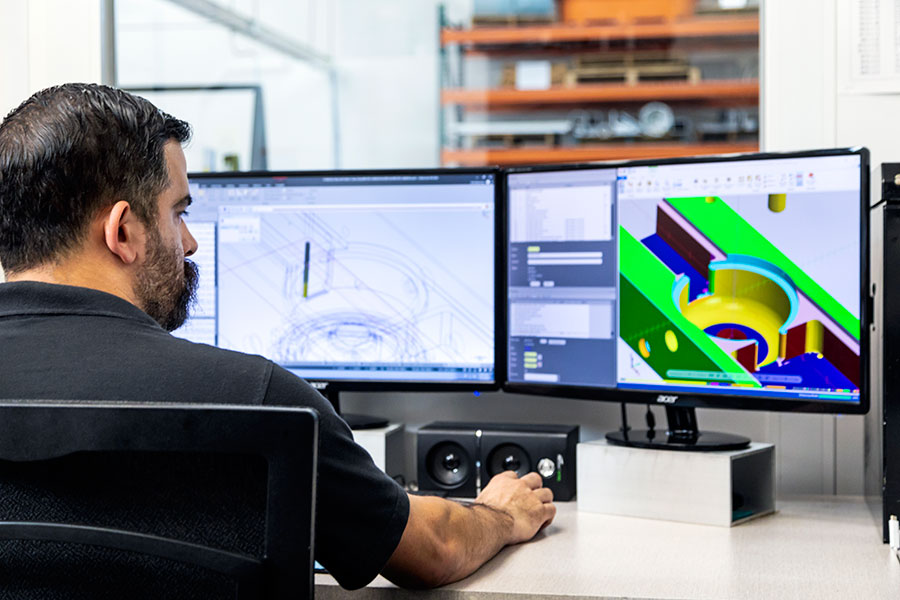

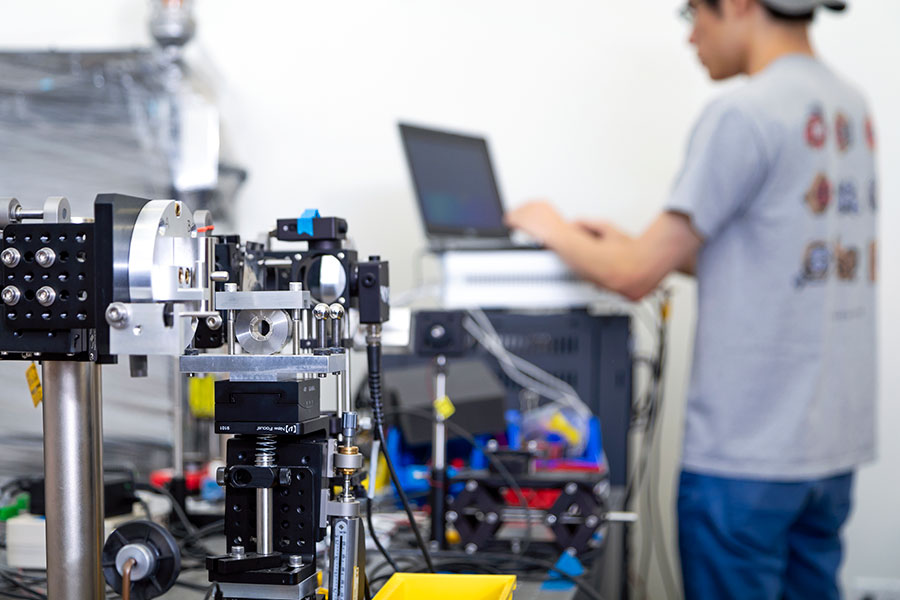

So you think you have an impossible research problem? No problem.

The team of multi-disciplinary scientists at RadiaBeam tackles monumental challenges through our directed research programs. In fact, we thrive on them. The complexities of accelerator technology demands expertise in many fields: fundamental, beam and radiation physics, high-powered electronics, vacuum engineering, optical analysis, and more.

Our experts are experienced at solving major puzzles, whether the outcome is a commercial spin-off or exploring the mysteries of the universe. Learn more

So you think you have an impossible research problem? No problem.

The team of multi-disciplinary scientists at RadiaBeam tackles monumental challenges through our directed research programs. In fact, we thrive on them. The complexities of accelerator technology demands expertise in many fields: fundamental, beam and radiation physics, high-powered electronics, vacuum engineering, optical analysis, and more.

Our experts are experienced at solving major puzzles, whether the outcome is a commercial spin-off or exploring the mysteries of the universe. Learn more

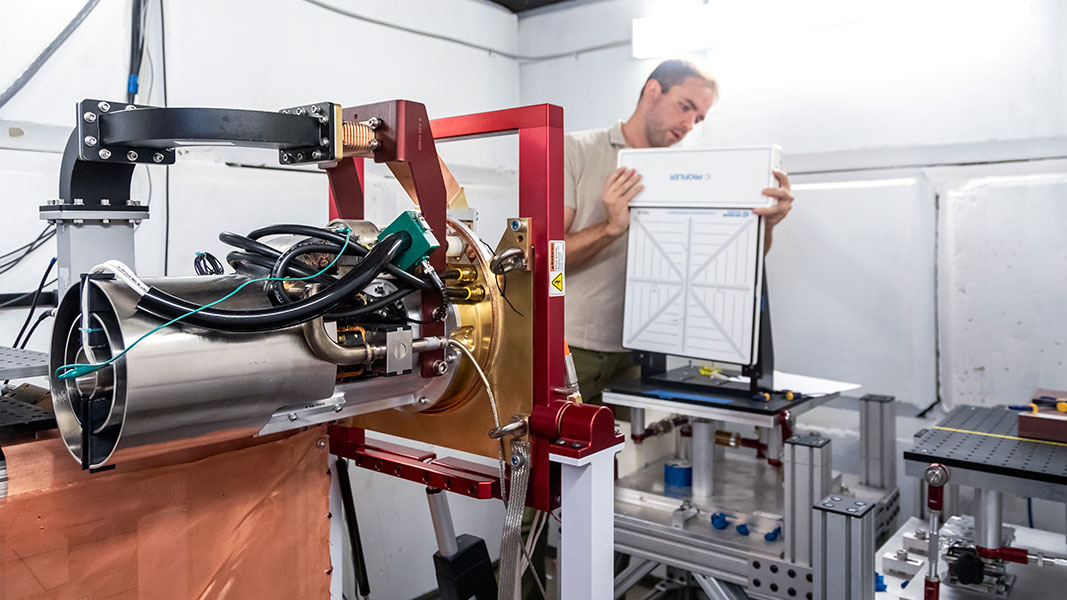

Colliders and light sources for national labs and universities: serving the needs of big science

Complete linac systems. Accelerating structures. Magnets. RF structures. Diagnostics. Detectors. When your laboratory or project requires an accelerator-related solution, RadiaBeam will make it happen seamlessly, economically and on-time. RadiaBeam’s components can be found on the most demanding beamlines around the world, such as LCLS, PAL-XFEL, CERN and FERMI at Trieste. We have R&D centers in the U.S. and Europe. Learn more

Colliders and light sources for national labs and universities: serving the needs of big science

Complete linac systems. Accelerator structures. Magnets. RF structures. Diagnostics. Detectors. When your laboratory or project requires an accelerator-related solution, RadiaBeam will make it happen seamlessly, economically and on-time. RadiaBeam’s components can be found on the most demanding beamlines around the world, such as LCLS, PAL-XFEL, CERN and FERMI at Trieste. We have R&D centers in the U.S. and Europe. Learn more

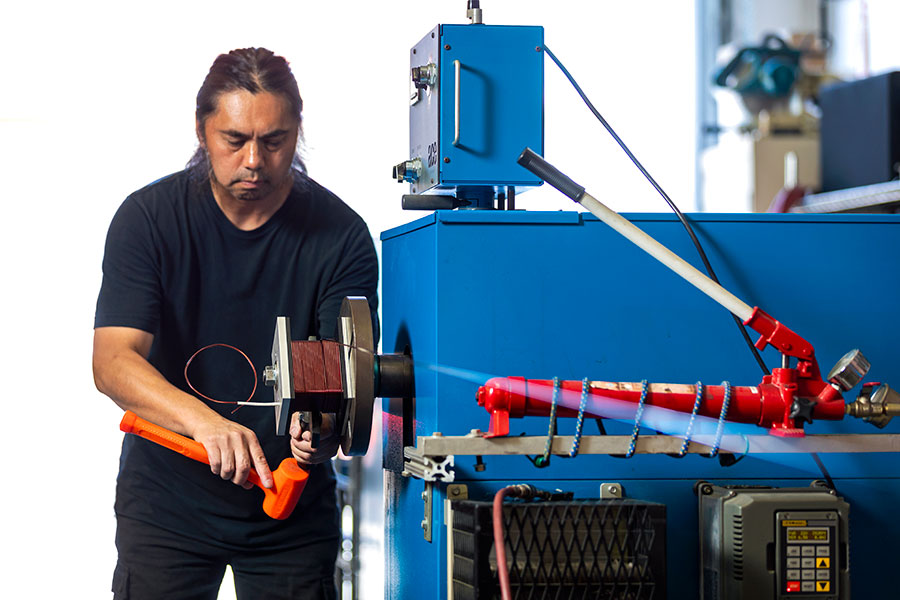

3-D printing: opening up new possibilities

RadiaBeam is working on an innovation to radically transform the way accelerators are made: 3-D printing, also known as Additive Manufacturing (AM). AM enables us to build-in complex cooling channels that can’t be fabricated with conventional technology, achieving higher average power without higher cost. We’re converting an electron beam welder to utilize E-beams to fabricate a new source of E-beams! It’s all part of RadiaBeam’s mission to transform ideas into physical reality. Learn more

3-D printing: opening up new possibilities

RadiaBeam is working on an innovation to radically transform the way accelerators are made: 3-D printing, also known as Additive Manufacturing (AM). AM enables us to build-in complex cooling channels that can’t be fabricated with conventional technology, achieving higher average power without higher cost. We’re converting an electron beam welder. utilizing E-beams to fabricate a new source of E-beams! It’s all part of RadiaBeam’s mission to transform ideas into physical reality. Learn more