IRRADIATORS

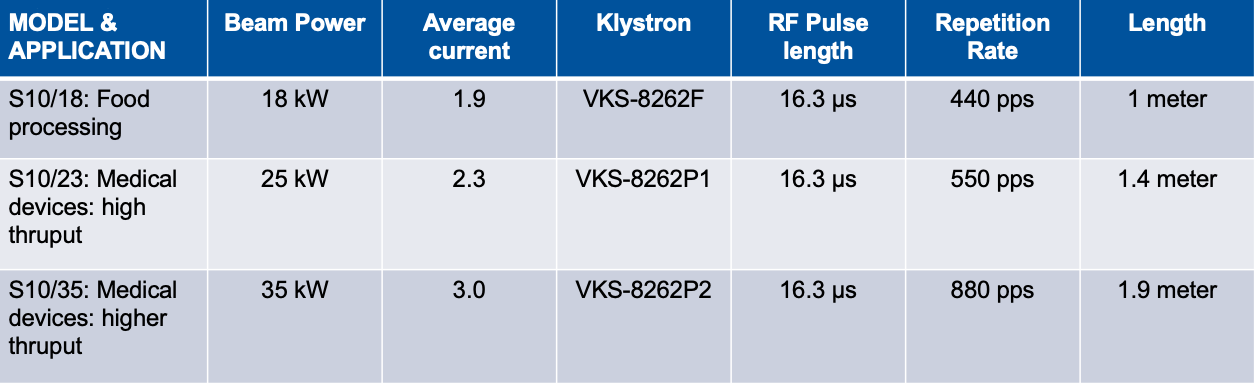

Wherever you need to be on the power spectrum, RadiaBeam offers a full range of accelerator-based irradiators to fit your size requirements, improving safety and throughput. We have compact, self-contained irradiators in the 1 – 3 kW range for applications including research, blood irradiation, and the sterile insect technique (SIT). Our high power 5 – 10 MeV linacs provide U.S. made 20 – 35 kW solutions for large scale service and manufacturing facilities for sterilization and food irradiation. Wherever you need to be on the power spectrum, RadiaBeam offers a full range of accelerator-based irradiators to fit your size requirements, improving safety and throughput. We have compact, self-contained irradiators in the 1 – 3 kW range for applications including research, blood irradiation, and the sterile insect technique (SIT). Our high power 5 – 10 MeV linacs provide U.S. made 20 – 35 kW solutions for large scale service and manufacturing facilities for sterilization and food irradiation.

STERILIZE, TREAT, OR TEST WITHOUT HIGH-RISK ISOTOPES OR CHEMICALS

Our irradiators, based on innovative particle accelerator technology, are a U.S.-made, high-throughput replacement for radioisotope-based (Co-60, Cs-137) and toxic gases (Ethylene Oxide). National security and human safety concerns are driving replacement of isotope-based systems by electronic sources. But alternatives based on X-ray tubes don’t produce adequate energy for effective penetration. RadiaBeam’s irradiators deliver high-energy electron beams and X-rays for a wide range of applications safely, uniformly, and efficiently.

SELF-CONTAINED, COMPACT IRRADIATORS IN YOUR CHOICE OF CONFIGURATION

Our self-contained irradiators are available in a range of configurations to fit your application. Surface irradiation? 1 MeV. In-line irradiation of medical devices? 2 – 4 MeV. Need energy variability? No problem.

Other options include types of output (electrons or X-rays), dosing schemes, types of beam spreading, and beam orientation. For example, our self-contained system for SIT (Sterile Insect Technique) uses a horizonal X-ray output to uniformly irradiate a rotating canister. A vertical e-beam system is best for in-line product sterilization.

WE’RE FIERCELY INDEPENDENT, FASTER AND MORE FLEXIBLE WHETHER YOU NEED COMPONENTS OR A FULL SYSTEM

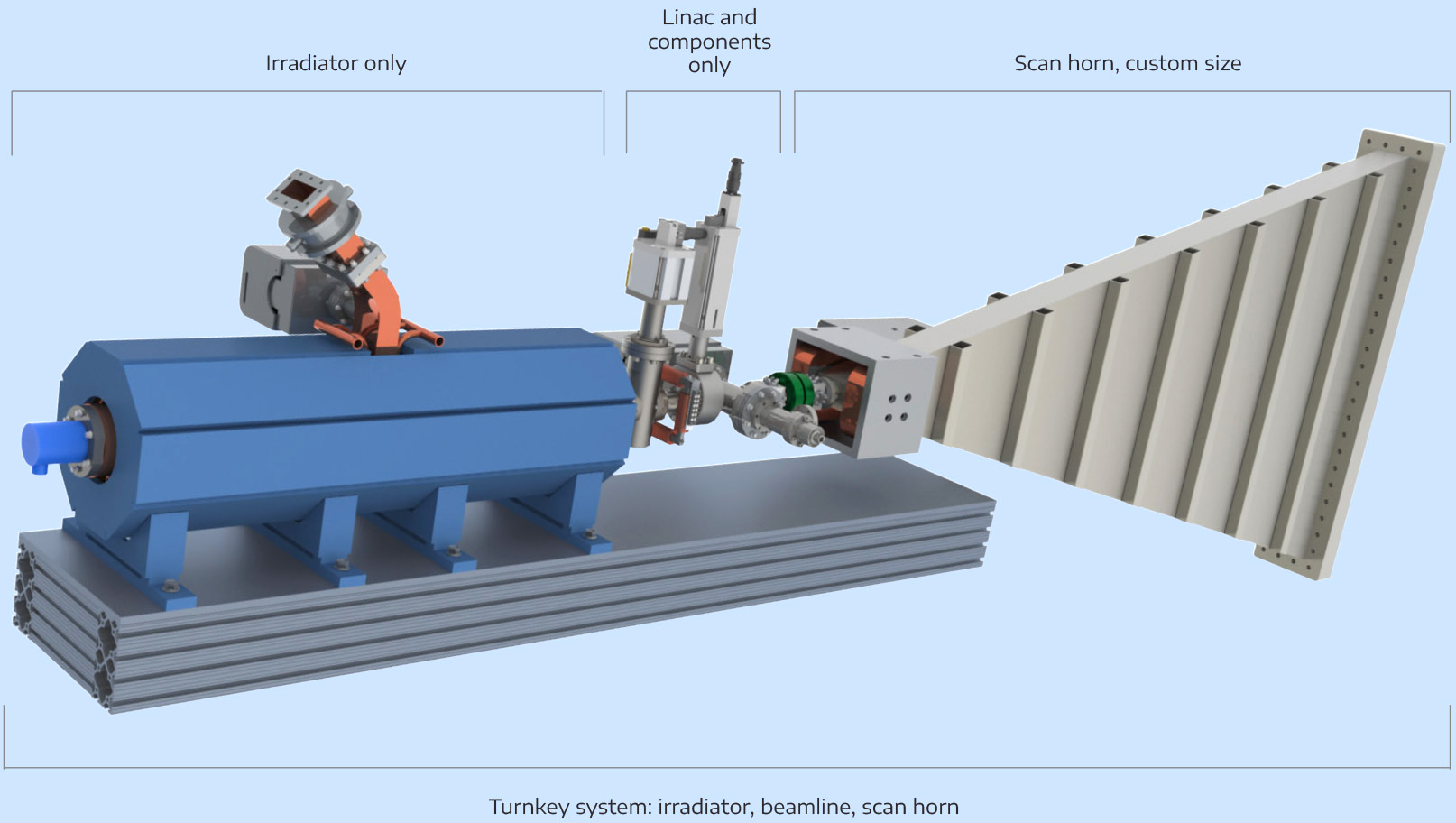

RadiaBeam is different from our competition in many ways. We’re proudly independent and U.S. based, with the flexibility to offer either drop-in ready components or complete turnkey systems, with a faster turnaround time. Need an OEM irradiator alone, or a linac head? No problem. Or, come to us for a turnkey system end-to-end for your production line, from beamline to irradiator to customized scan horn. Either way, our turnaround time beats our competition hands-down thanks to our modular system design.

HOW MUCH THROUGHPUT DO YOU NEED?

We offer a full range of power and throughput levels, and will consult with you to match our performance to your application.

HIGH POWER LINACS FOR PANORAMIC IRRADIATORS

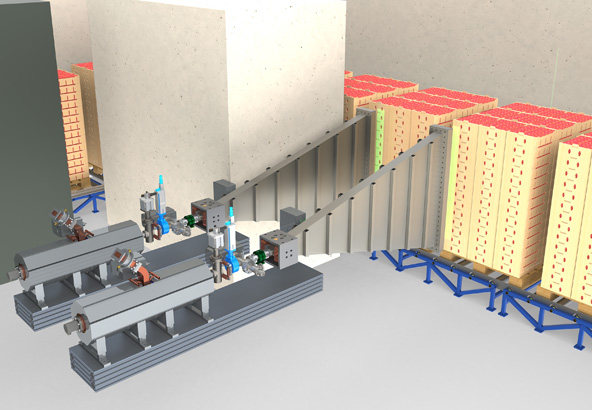

Integration into your production line

Our high-power linacs can be used in panoramic irradiator facilities, delivering high-powered electron beams and X-rays that achieve optimum penetration at speed as cartons with medical disposables or food move along the conveyor. We will configure a system to fit your operation: Full beamline with delivery horn, a turnkey irradiator with complete control system, or, in collaboration with our partners, a complete facility from the ground up.

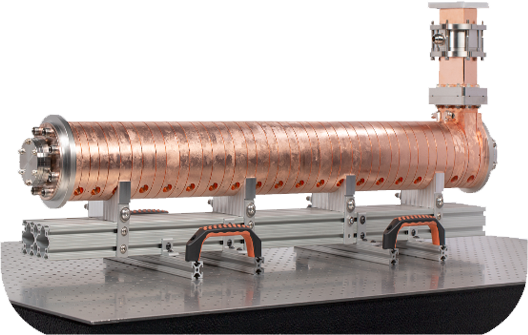

RF technology: Efficiency and power

The most cost-effective accelerator technology with sufficient power for sterilization is called the Radio Frequency Linear Accelerator, or “linac.” The electron beam is accelerated to a kinetic energy of 2– 10 MeV using a resonant radiofrequency structure. The beam is then scanned in the transverse direction, while a conveyor moving in the remaining direction ensures that the product is irradiated uniformly.

Complete Facility

Structure only

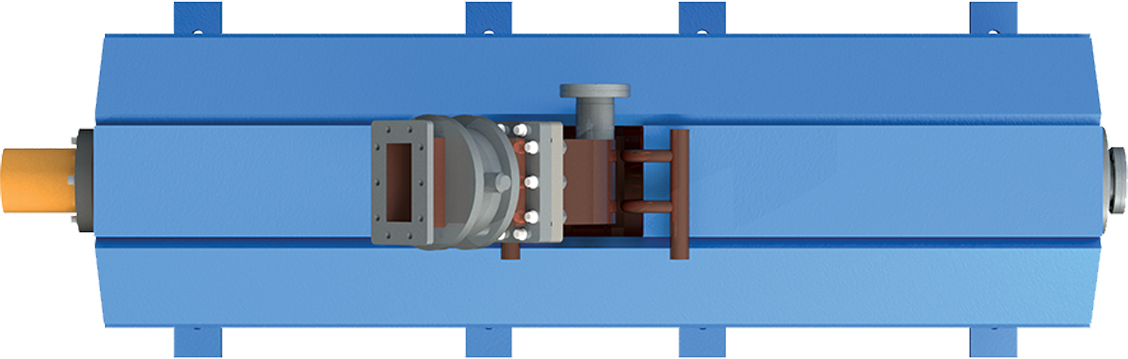

COMPONENTS AND SYSTEMS FOR OEM PARTNERS

RadiaBeam also offers irradiator system configurations and components for original equipment manufacturers, whether you need the irradiator structure only or the complete source. Our team will work closely with you customize a component or system that meets your objectives. We offer 5 and 7.5 MeV X-ray sources and 10 MeV electron irradiators with 18 – 35 kW of beam power, as well as 2 – 4 MeV, 2 kW sources for in-line irradiation.

Accelerating Structure